Business Type:Manufacturer

Country/Region:China

Ddu Verified

HOT Rank

Henan Subcritical Extraction Biological Technology Co., Ltd

We are professional supplier of biological plant extraction machine,medicine extraction machine.

Business Type:Manufacturer

Country/Region:China

Ddu Verified

HOT Rank

Henan Subcritical Extraction Biological Technology Co., Ltd is engaged in subcritical extraction technology at low temperature as well as natural products development and utilization in China.

Moringa oil comes from the seeds of the Moringa oleifera tree, a fast growing leafy tree species native to the Himalayas. The seeds, harvested from their pods, yield approximately 35–40% of non-drying Moringa oil, also known as Ben oil or Behen oil.

Moringa seed oil is clear and smells nutty. Thanks to the numerous antioxidants in it, the oil does not become rancid for several years after it is produced. This makes it sought after for a number of health and beauty applications.

Although the oil is viable for use as a cooking oil, its high demand and low levels of production do not make it conducive for every day use as a dietary product. However, small amounts of oil are often used in recipes calling for a rich, nutty flavor, such as stir-fried dishes and marinades. Moringa oil is also occasionally used as a dressing for vegetables, salads, and other green dishes.

Moringa oil is among the most desired oils in the formulation of skin care products and cosmetics, chosen for its many antioxidants and documented skin-rejuvenating properties. These antioxidants do wonders for aging and nutrient-depleted skin. You can experience these benefits today!

Our patent technology:

Subcritical fluid mainly consists of liquefied propane and butane. The boiling point of the solvent composition is mostly under 0 ℃, boiling point of propane is 42.07 ℃, boiling point of butane is 0.5 ℃. Its form differs under different conditions, such as gas for normal pressure, liquid for after pressure.

The advantages of subcritical extraction technology at low temperature

(1) The meal quality is good after being pulped, the invariance rate of water-soluble protein is greater than 95%, meal in the residual oil is less than 1%, the residual solvent is less than 50 PPM;

(2) Low solvent consumption, tons of material consumption is less than 6 kg;

(3) 90 ℃hot water is needed instead of steam, relatively 70% heat energy can be saved in using number six solvent;

(4) pollution free, environmental protection engineering;

(5) the color of extraction oil is light, low content of lecithin, residual solvent is less than 1 PPM;

Advantages of Subcritical Oil Extraction Machine

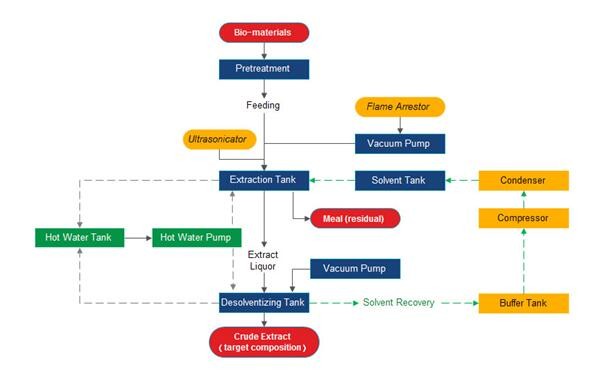

Subcritical extraction is the drawing out of active substance from natural plants, animals and any other bio material. Pressure of approximately 0.3-0.8 MPa is used in the extraction process using the gaseous agent that turns fluid In such kind of pressure. The state is necessary as it increases permeability, transfer rate and dissolving capability. It has proved effective and efficient in the extraction of oils such as essential and solvent extraction oils; also the plant proteins and natural pigments.

Low Temperature Solvent Extraction Process

Capacity range: 0.1~200 T/D

How Subcritical Extraction is Better than Traditional Solvent Extraction?

It ensures the residual solvent is <50ppm with residual oil less than 1% Whatever remains from residual oil meals or cakes still retain their natural active ingredients thus rendering

them of high and better quality than those which traditional oil mill was used on. Solvent needed for processing is less than 8kg way lower than what could have been spent in traditional solvent extraction.

Great deal of energy is saved because steam is not necessary. Subcritical extraction is the best when it comes to extraction of precious oil, vegetable protein or natural pigment. It has high extraction ratio as compared to the traditional method. The environment is well catered for. There is zero pollution due to discharge.

How Subcritical is Better than Supercritical Extraction?

The word "super" before supercritical does not necessarily make supercritical extraction better than subcritical in any way. On the contrary, it still retains the benefits of supercritical extraction and beats it further on the following: