Business Type:Manufacturer

Country/Region:China

Ddu Verified

HOT Rank

Henan Subcritical Extraction Biological Technology Co., Ltd

We are professional supplier of biological plant extraction machine,medicine extraction machine.

Business Type:Manufacturer

Country/Region:China

Ddu Verified

HOT Rank

Pumpkin Seed Oil Subcriitcal Extraction Machine

Pumpkin seed oil has an intense nutty taste and is rich in polyunsaturated fatty acids. Browned oil has a bitter taste. Pumpkin seed oil serves as a salad dressing. The typical Styrian dressing consists of pumpkin seed oil and cider vinegar. The oil is also used for desserts, giving ordinary vanilla ice cream a nutty taste. It is considered a real delicacy and a few drops are added to pumpkin soup and other dishes.

Advantages of Subcritical Oil Extraction Machine

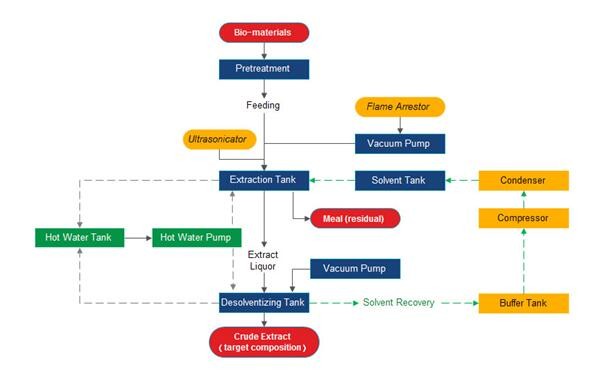

Subcritical extraction is the drawing out of active substance from natural plants, animals and any other bio material. Pressure of approximately 0.3-0.8 MPa is used in the extraction process using the gaseous agent that turns fluid In such kind of pressure. The state is necessary as it increases permeability, transfer rate and dissolving capability. It has proved effective and efficient in the extraction of oils such as essential and solvent extraction oils; also the plant proteins and natural pigments.

Low Temperature Solvent Extraction Process

Capacity range: 0.1~200 T/D

How Subcritical Extraction is Better than Traditional Solvent Extraction?

It ensures the residual solvent is <50ppm with residual oil less than 1% Whatever remains from residual oil meals or cakes still retain their natural active ingredients thus rendering

them of high and better quality than those which traditional oil mill was used on. Solvent needed for processing is less than 8kg way lower than what could have been spent in traditional solvent extraction.

Great deal of energy is saved because steam is not necessary. Subcritical extraction is the best when it comes to extraction of precious oil, vegetable protein or natural pigment. It has high extraction ratio as compared to the traditional method. The environment is well catered for. There is zero pollution due to discharge.

How Subcritical is Better than Supercritical Extraction?

The word "super" before supercritical does not necessarily make supercritical extraction better than subcritical in any way. On the contrary, it still retains the benefits of supercritical extraction and beats it further on the following:

The less pressure also comes in handy in terms of industrialization scale production with which would not be possible in supercritical extraction.